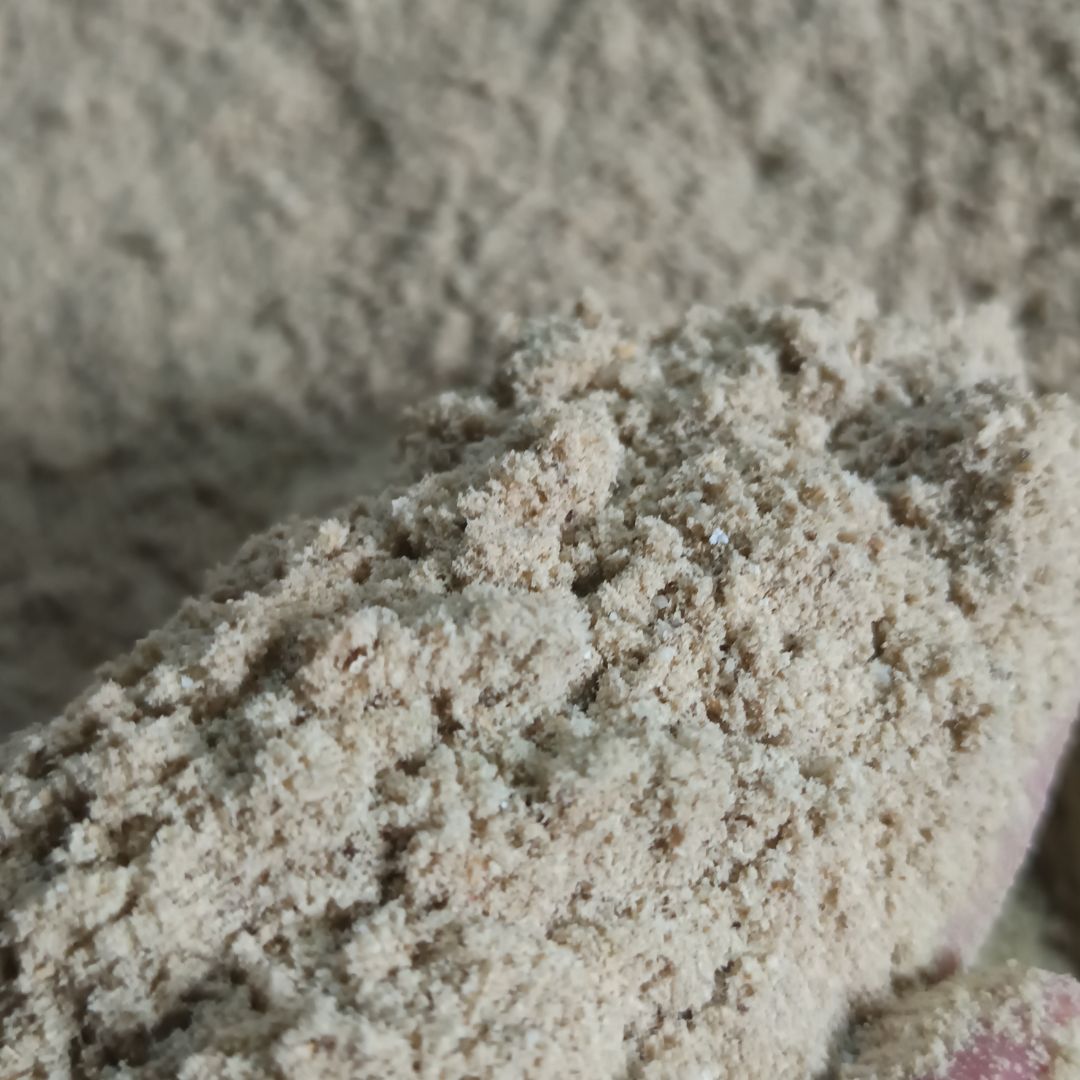

High-quality rice bran that is clean, uniform, and free from contaminants

Rice bran is a by-product of the rice milling process, obtained from the outer layers of the rice grain during the dehusking and polishing stages. It consists of a mixture of the aleurone layer, seed coat, and small portions of the endosperm, making it a valuable nutritional source, especially in the animal feed industry.

Our rice bran is produced using a modern Rice Milling Unit (RMU) equipped with a controlled separation system, ensuring a high-quality product that is clean, uniform, and free from contaminants such as stones, sand, or heavy metals.

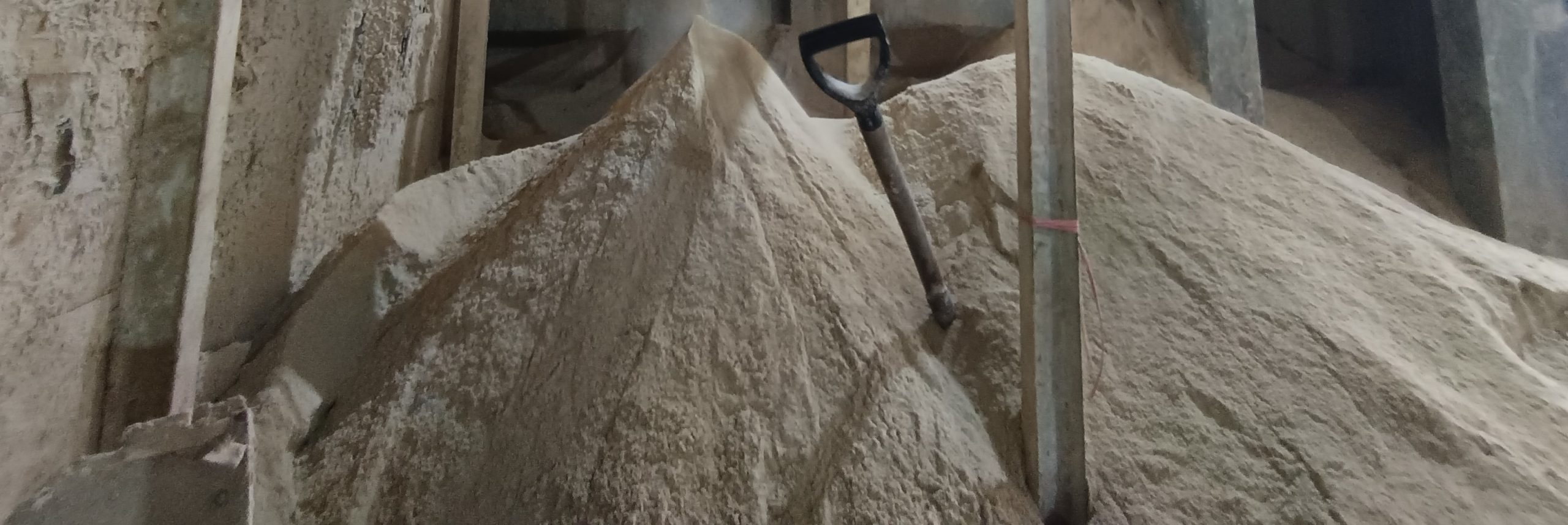

Processing & Storage

The production of rice bran is carried out using advanced milling technology to ensure product quality, hygiene, and consistency. Our facility operates a modern Rice Milling Unit (RMU) system equipped with precisely controlled separation and screening mechanisms.

To maintain product purity, the bran is carefully screened and filtered to produce a material that is clean, fine, and homogeneous. The final product is stored in a controlled dry environment and packed in 25–50 kg sacks, ready for distribution.

This modern processing method ensures that our rice bran meets industrial standards for use in animal feed, composting, and agricultural applications — both for domestic and export markets.

Primary Applications

Animal Feed

Used as a raw material in feed formulations for poultry, cattle, goats, pigs, and fish due to its beneficial energy, protein, and fiber content.

Fermentation Industry

Serves as a microbial substrate in the production of silage feed or probiotics.

Compost Material

Blended into compost mixtures to enhance organic nutrient content.

Additional Nutritional Source

Applied in the formulation of organic and herbal animal feeds.